|

Rotary Club of Secunderabad Sunrise |  |

Vocational Visit to Vizagsteel plant on 24th Oct'04:

Coke Ovens & Coal Chemical Plant

Coking coal after selective crushing and proper blending is subjected to destructive deistillation (heating in the absence of air) in the Coke Ovens. After heating for nearly a period of 16-18 hours at a temperature of about 1100oC, coke is obtained and is used as a fuel as well as reducing agent in the Blast Furnace. The Coke Ovens of VSP are engineering feats by themselves. They are the tallest ovens metre constructed in the country. The Plant has 3 batteries of 7mtr. tall ovens with each battery consisting of 67 ovens. Another feature is the dry cooling of coke carried out by the inert gas nitrogen thus, reducing pollution considerably. Besides a bio-chemical plant separately undertakes the treatment of effluents. By-products like benzene, toluene, xylene, napthalene, coal tar, creosote oil, pitch, ammonium sulphate and benzol products are also recovered from the coke ovens gas. VSP produces, among other by-products, pushkala a prime fertilizer based on ammonium sulphate.

Sinter Plant

Iron ore fines, coke breeze, limestone and dolomite along with recycled metallurgical wastes are converted into agglomerated mass at the Sinter Plant, which forms 80% of iron bearing charge in the Blast Furnace. The Sinter Plant comprises of two sinter machines each having 312 square metres of grate area with a total production capacity of 5.256 million tonnes per annum.

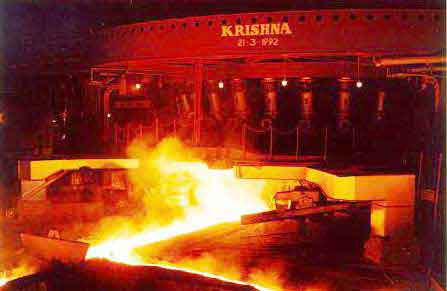

Blast Furnace

VSP has two Blast Furnaces with an effective volume of 3200 cu.m. each of which are the largest in the country. Blast Furnace is charged with coke, iron ore and sinter from the top and produces about 5000 tonnes of molten iron per day. Its novel circular cast house with four tap holes ensures continuous tapping of hot metal. The annual production capacity of these Blast Furnaces is 3.4 million tonnes of liquid iron.

Steel Melt Shop & Continuous Casting

Three Top blown converters, each of 133 cu.m. volume, produce a total of 2.7 million tonnes of liquid steel per annum. This liquid steel thus produced is casted in six-4 strand bloom casters. A special feature in energy conservation is the collection of Converter gas to be used as a fuel in the plant. The entire molten steel at VSP is continuously cast at the radial type continuous casting machines resulting in significant energy conservation and better quality steel. 100% Continuous casting on such a large scale has been conceived for the first time in India.

Rolling Mills

The cast blooms from continuous casting department are heated and rolled in the three high speed and fully automated rolling mills namely Light & Medium Merchant Mill, Wire Rod Mill and Medium Merchant & Structural Mill, to produce various long products like Reinforcement bars, rounds, squares, flats, angles, channels, billets, wire rods etc. Technologies adopted at Rolling Mills include world-class Stelmor and Tempcore processes.